process of circuit board assembly companies

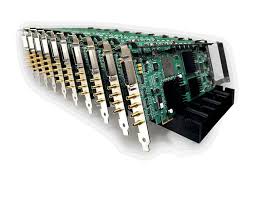

The process of circuit board assembly companies encompasses several intricate steps, each essential in transforming raw materials into functional printed circuit boards (PCBs). Understanding this process sheds light on the complexity and precision involved in manufacturing electronic components that power a myriad of devices in our modern world.

The journey begins with design. circuit board assembly companies collaborate closely with clients to understand their requirements and specifications. Design engineers then translate these needs into PCB layouts using specialized software. These layouts dictate the arrangement of electronic components and conductive pathways on the board, taking into account factors like signal integrity, thermal management, and manufacturability.

Once the design is finalized, fabrication commences. This involves the production of the actual PCBs using specialized manufacturing techniques. The process typically starts with substrate preparation, where the base material, often fiberglass-reinforced epoxy laminate, is cleaned and coated with a layer of copper. Next comes imaging, where the PCB layout is transferred onto the substrate using a photosensitive material and UV light. The exposed areas are then etched away, leaving behind the desired copper traces.

Can you explain the process of circuit board assembly companies?

Drilling is the next step in the fabrication process. Small holes are drilled into the PCB to accommodate through-hole components and vias, which provide electrical connections between different layers of the board. Surface finishing techniques such as solder mask application and surface plating are then applied to protect the copper traces and improve solderability.

With the PCBs fabricated, the assembly process can begin. This involves mounting electronic components onto the board and creating electrical connections between them. Circuit board assembly companies employ both manual and automated assembly techniques depending on the complexity and volume of the project. For high-volume production runs, automated assembly equipment such as pick-and-place machines and reflow soldering ovens are used to maximize efficiency and throughput.

Precision and accuracy are paramount during the assembly process. Skilled technicians or robotic arms carefully place each component onto the PCB following the layout specified in the design files. Solder paste, a mixture of flux and solder particles, is then applied to the pads on the PCB, and the components are heated in a reflow oven to create strong and reliable electrical connections.

Quality control is a critical aspect of circuit board assembly companies’ operations. Rigorous testing procedures are implemented to detect any defects or irregularities in the assembled PCBs. These tests may include electrical testing, functional testing, and visual inspection using advanced equipment and techniques. Any faulty PCBs are identified and rectified to ensure that only high-quality products are delivered to clients.

Throughout the process, circuit board assembly companies work closely with their clients to provide design assistance, prototyping, and technical expertise. Clear communication and collaboration are essential to ensuring that the final product meets or exceeds the client’s expectations in terms of performance, reliability, and cost-effectiveness.

In conclusion, the process of circuit board assembly companies is a complex and multi-faceted journey that involves design, fabrication, assembly, and quality control. By leveraging advanced technology, skilled craftsmanship, and stringent quality control measures, these companies enable the production of high-quality PCBs that power the electronic devices we rely on every day.