Printed Circuit Board Maker From Moisture

Moisture is one of the most harmful factors to printed circuit boards. Even the smallest droplet of moisture can cause warping, rust, and malfunction. Keeping humidity and moisture at bay is crucial when creating, assembling, storing, and shipping electronics and PCBs. Luckily, there are many methods to leverage during the fabrication, assembly, storage and shipping processes to help prevent moisture exposure.

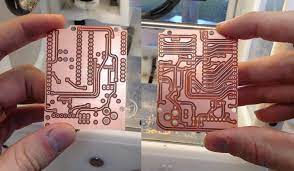

During the manufacturing process, PCBs may accumulate moisture due to improper handling and environmental conditions. This moisture can then damage the conductive pathways on the board. This deterioration is known as delamination, and it’s a common cause of failure in electronic devices.

Moisture can also cause corrosion, a chemical reaction that can ruin the functionality of a circuit board. This is caused by water containing electrolytes coming into contact with a metal surface, forming dendrite structures that short out the electrical currents. The effects of corrosion can be devastating to a device, and it’s important for pcb board maker and assemblers to avoid it at all costs.

One of the most common ways moisture can be prevented from damaging a circuit board is through conformal coating. This is a spray-on protective layer that can be applied to the surface of a circuit board. This coating can help protect the circuit board from oxidation, moisture, and debris, and it can also improve conductivity. Conformal coating isn’t recommended for solder joints, however, because it can disrupt the flow of electricity and lead to a short circuit.

How to Protect a Printed Circuit Board Maker From Moisture

Another way to prevent moisture from damaging a circuit board is to store it in a dry environment. This can be achieved by placing the board in a box with an airtight seal. It is also helpful to wrap the board in a sheet of bubble film. Bubble film has excellent moisture absorption properties and can significantly reduce the risk of water damage.

There are also moisture-proof bags available that can provide a nearly complete vapor barrier. These bags are often used to package and ship products, including electronics and medications. They can be purchased on aliexpress, and they’re an inexpensive option for preventing moisture from damaging your circuit board.

For more critical electronics or total water immersion, potting or sealing is the best method for protecting a circuit board. Potting or encapsulating a circuit board in a solid block of a waterproof polymer compound offers the ultimate protection from moisture and condensation. This method of protection requires careful design, however. The potting or encapsulation material needs to be chosen carefully, and small openings in the coating from connectors and test points require extra sealing. This type of protection is also more costly than other moisture-proofing techniques.

Protecting printed circuit boards (PCBs) from moisture is crucial for ensuring their longevity and functionality. Moisture can lead to corrosion, short circuits, and overall degradation of the PCB components. Implementing proper protective measures is essential to safeguard PCBs from moisture-related damage. Here’s a comprehensive guide on how to protect a PCB maker from moisture: