industries commonly use pcb flex rigid

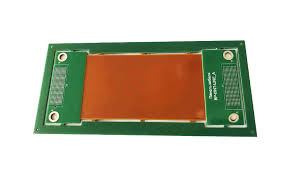

Flex-rigid printed circuit boards (PCBs) have become increasingly prevalent across a diverse range of industries, thanks to their unique combination of flexibility, durability, and compactness. These specialized PCBs offer a versatile solution for applications that require both rigid and flexible circuitry, making them invaluable in various sectors where traditional rigid PCBs may not suffice.

One industry that extensively utilizes PCB flex-rigid technology is the aerospace and defense sector. Aerospace applications demand lightweight, compact, and reliable electronic systems that can withstand extreme temperatures, vibrations, and mechanical stresses. Flex-rigid PCBs offer the flexibility and durability required for aerospace electronics, making them ideal for avionics, navigation systems, communication equipment, and military-grade electronics.

The medical industry also benefits significantly from the use of pcb flex rigid in devices such as medical implants, diagnostic equipment, monitoring devices, and wearable health trackers. These applications often require flexible circuitry to conform to the contours of the human body or to withstand repeated bending and flexing during use. Flex-rigid PCBs provide the necessary flexibility and reliability to ensure the performance and safety of medical electronics.

What industries commonly use pcb flex rigid?

Moreover, the automotive industry relies on flex-rigid PCBs for various applications, including vehicle infotainment systems, advanced driver assistance systems (ADAS), automotive lighting, and engine control units (ECUs). Flex-rigid PCBs offer space-saving solutions for automotive electronics, allowing manufacturers to optimize the layout of electronic components while ensuring resistance to harsh environmental conditions, temperature fluctuations, and mechanical vibrations.

The telecommunications industry is another major user of flex-rigid PCB technology, particularly in the development of high-speed data transmission systems, wireless communication devices, and networking equipment. Flex-rigid PCBs enable the integration of complex circuitry into compact and lightweight devices, facilitating seamless connectivity and data transfer in telecommunications networks.

Additionally, the consumer electronics sector extensively employs flex-rigid PCBs in products such as smartphones, tablets, laptops, wearables, and smart home devices. These applications benefit from the flexibility, durability, and space-saving capabilities of flex-rigid PCBs, allowing manufacturers to create sleeker, more compact, and feature-rich electronic devices that meet the demands of modern consumers.

In the industrial automation and robotics sector, flex-rigid PCBs play a crucial role in the development of advanced control systems, motion control modules, sensors, and actuators. These applications require rugged and reliable electronics that can operate in harsh industrial environments while providing precise control and feedback. Flex-rigid PCBs offer the necessary robustness and flexibility to withstand the rigors of industrial automation and robotics applications.

Furthermore, the renewable energy industry utilizes flex-rigid PCBs in solar energy systems, wind turbines, energy storage systems, and smart grid infrastructure. These applications require electronic components that can withstand outdoor exposure, temperature variations, and high humidity levels while maximizing energy efficiency and reliability. Flex-rigid PCBs provide a compact and durable solution for integrating electronics into renewable energy systems.

In conclusion, flex-rigid PCBs find widespread use across a multitude of industries, including aerospace, medical, automotive, telecommunications, consumer electronics, industrial automation, robotics, and renewable energy. Their versatility, reliability, and space-saving capabilities make them indispensable for applications that demand flexible yet robust electronic solutions. As technology continues to advance, the demand for flex-rigid PCBs is expected to grow, driving further innovation and expansion across various industries.